Labormac

About This Project

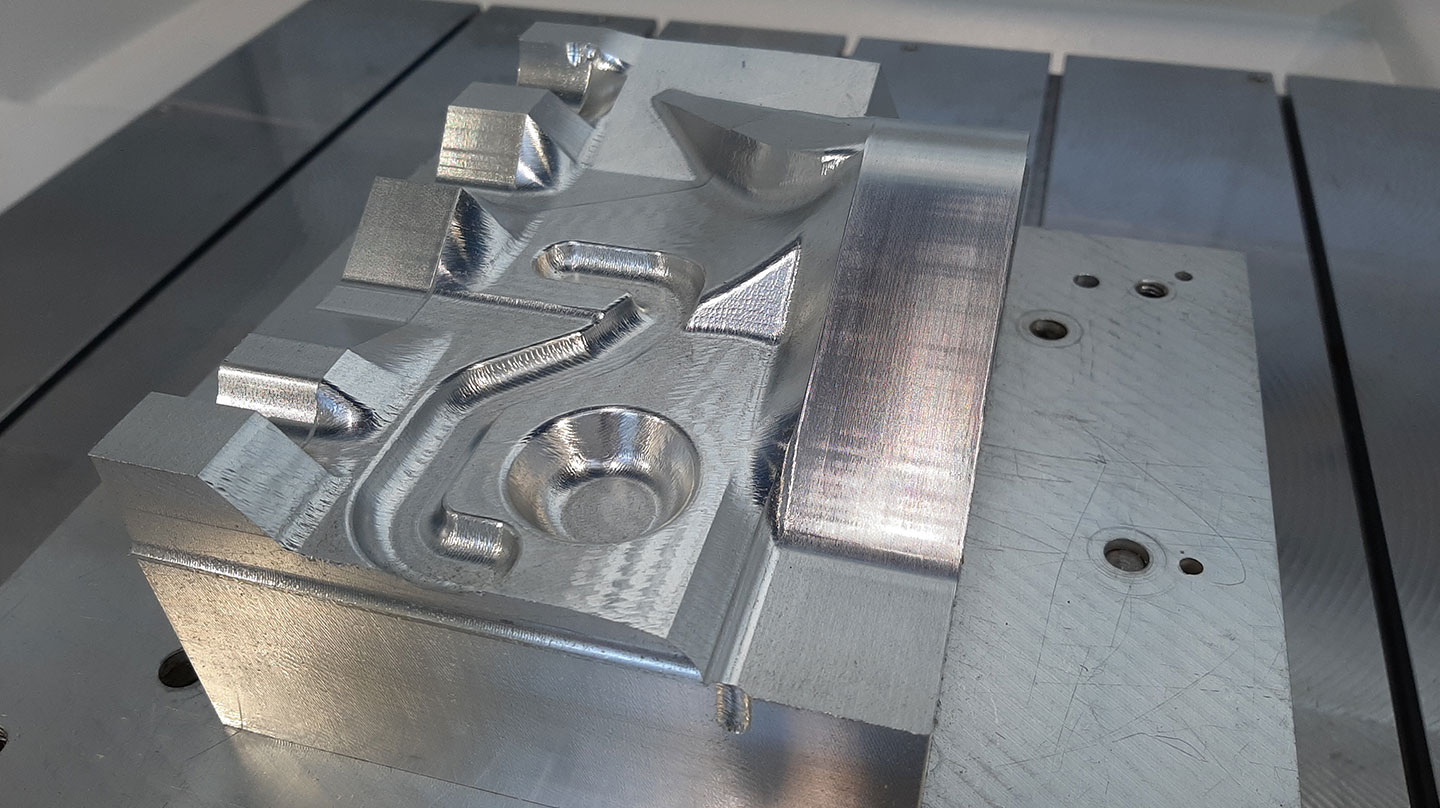

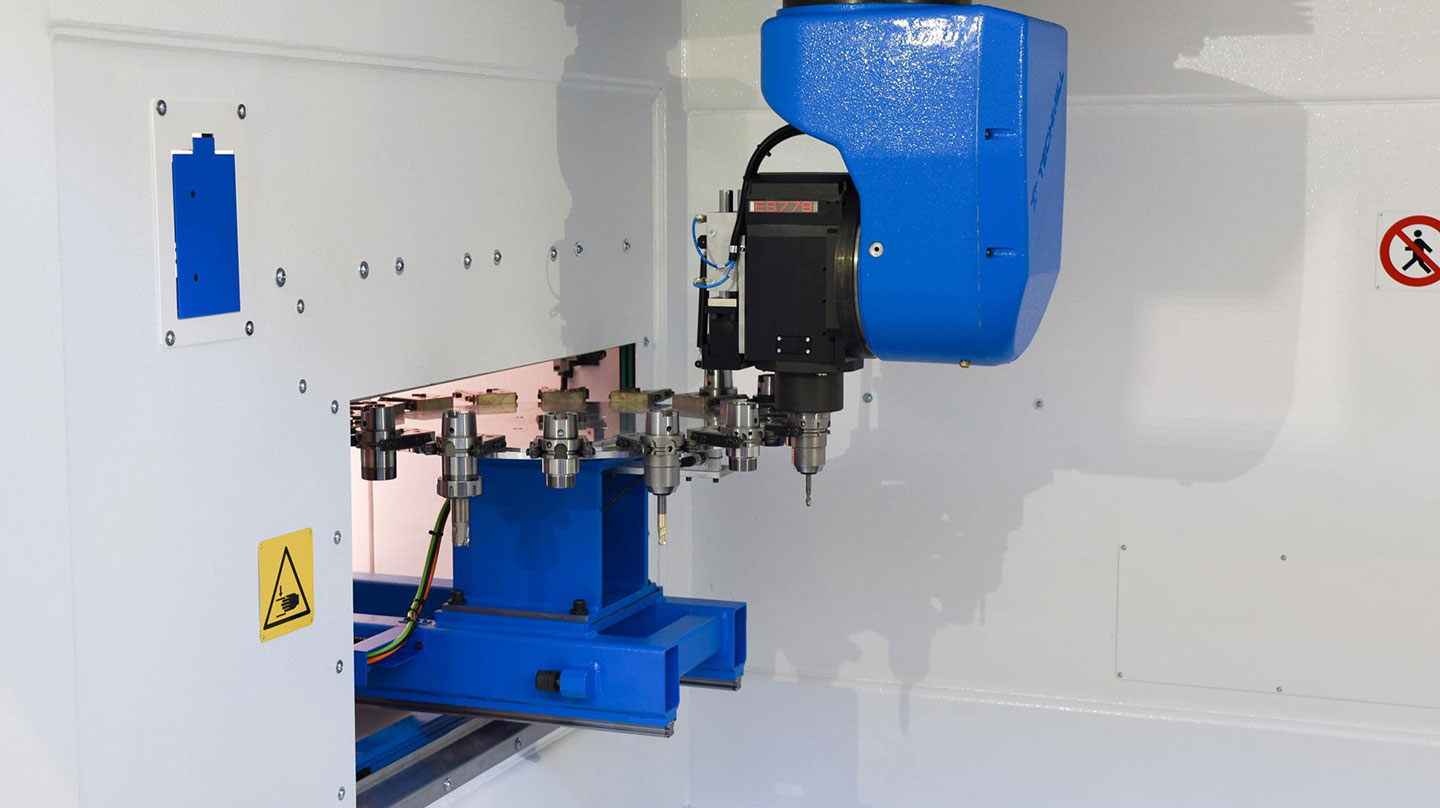

LaborMac is a 5-axis machining centre specifically developed to optimize the machining of molds and parts in aluminum and composite.

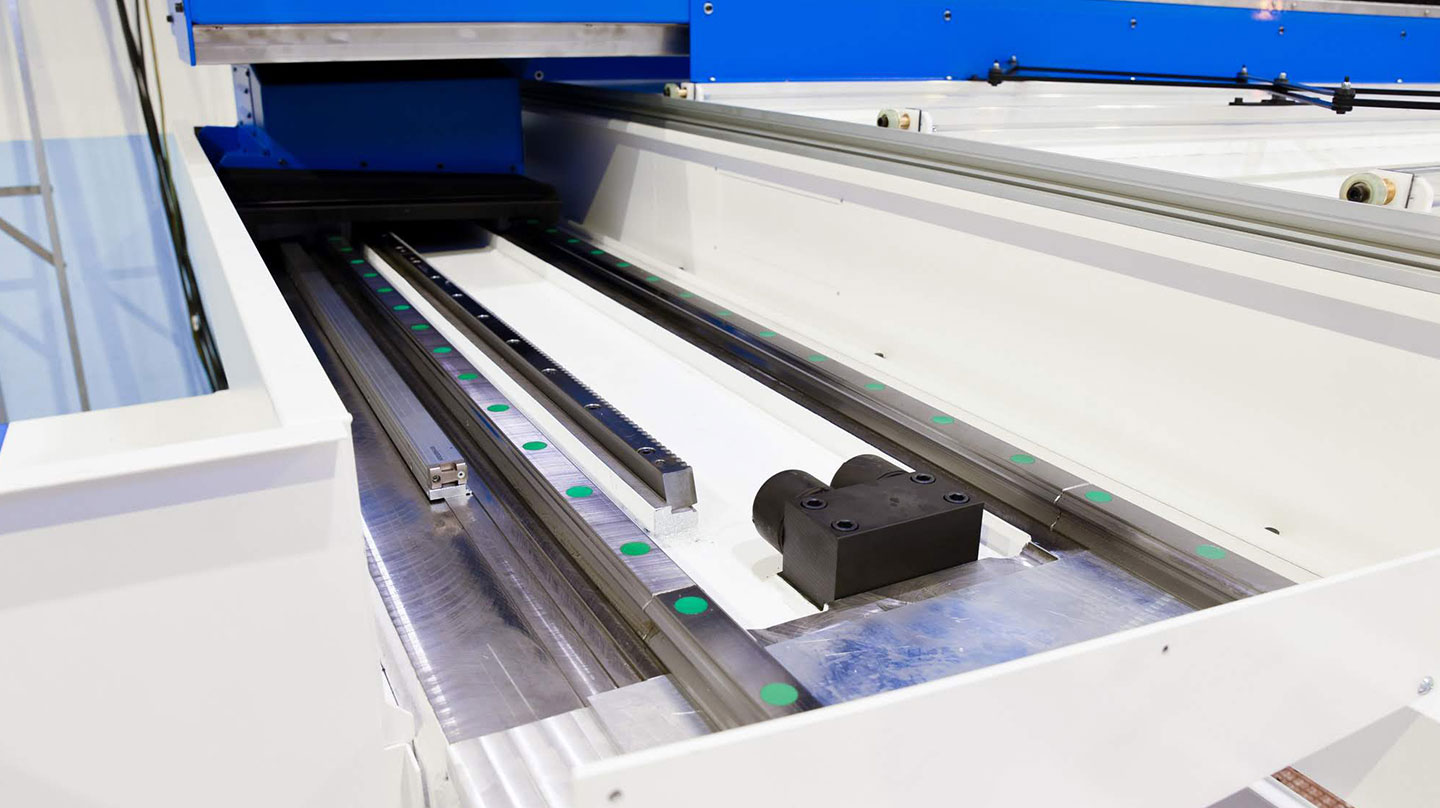

The extreme rigidity provided by the monolithic structure with Gantry type mobile portal on the Y axis, significantly limits the vibrations helping to achieve very good quality even at high speeds.

LaborMac version “A“, dedicated to aluminum machining typical of the automotive sector, is equipped with a working head of higher robustness, tool’s cooling system by chemical water, steel table with T-slots and two chips conveyors .

The version “C”, equipped with Oil Mist, offers instead high performance in modeling and trimming of composite materials and resins.

Technical data

| Axes Strokes | Axes Speed | |

| X | 2.600 mm | 80 m/min |

| Y | 1.500 mm | 80 m/min |

| Z | 1.000 – 1.200 mm | 40 m/min |

| A | +/- 120° | 40 m/min |

| C | +/- 365° | 30 m/min |

Spindle features

| Power | 15- 22 kW |

| Torque | 13,5 – 28 Nm |

| Speed | 20.000 – 24.000 rpm |

Materials

Composites

Resin

Aluminum

Light Alloys