REFRIGERATOR DOORS

About This Project

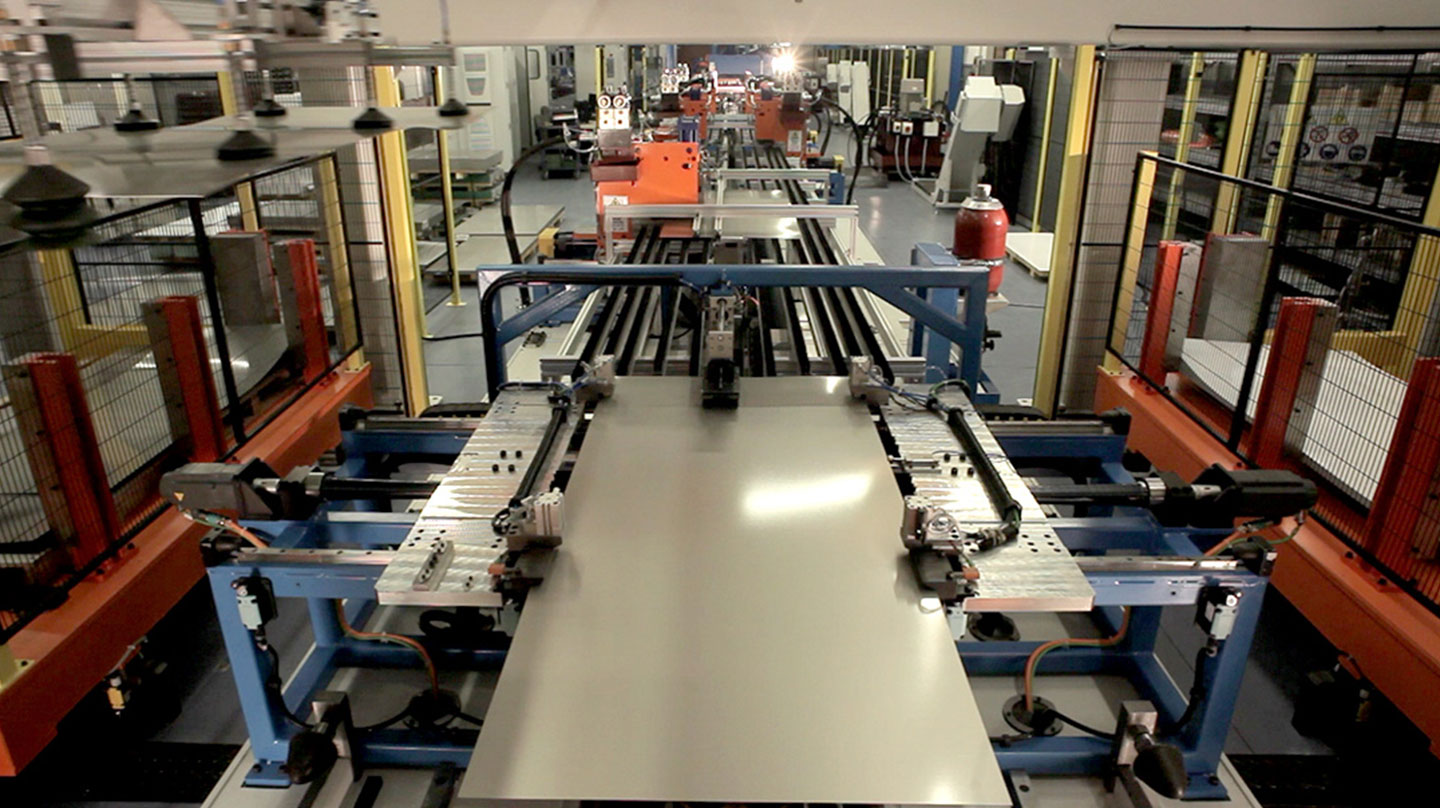

COMI TEAS designs and manufactures completely automatic and performing systems with the highest degree of customization to produce external doors for refrigerators according to the multiple aesthetic proposals offered by customers’ R & D divisions

Our systems can realize

- Flanged doors

- Arched doors

- Doors with wide central and lateral drawing

- Bent square doors

- Doors with integrated door handles

- Doors with dedicated profiles

Features

The COMI TEAS door production lines can start either from coils or from pre-cut blanks with different thicknesses and types of material (black or pre-painted metal sheet or stainless steel).

The range of dimensions and characteristics of the models produced within the same production plant can be completely customized.

Through automatic and integrated transfers the metal sheet is then centered, trimmed if necessary, and then moved through various work benches according to the specific needs of the model to be produced.

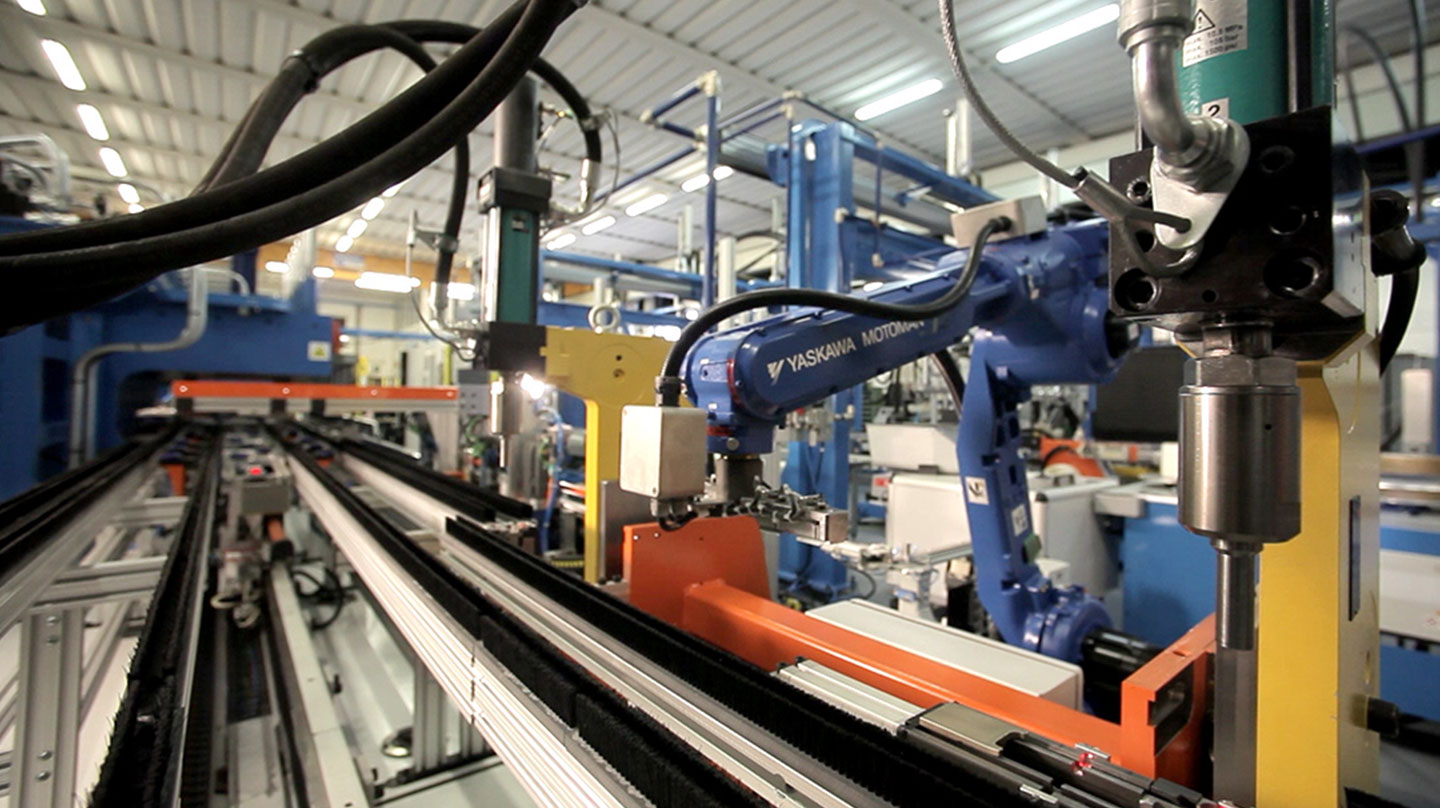

The generally involved stations include blanking units, customization presses, bending machines, door separation units, short side flanging units and possible reinforcement application.

The folds of the various panels can be made using interpolated electric bending machines, linear or universal bending according to the various types of product.

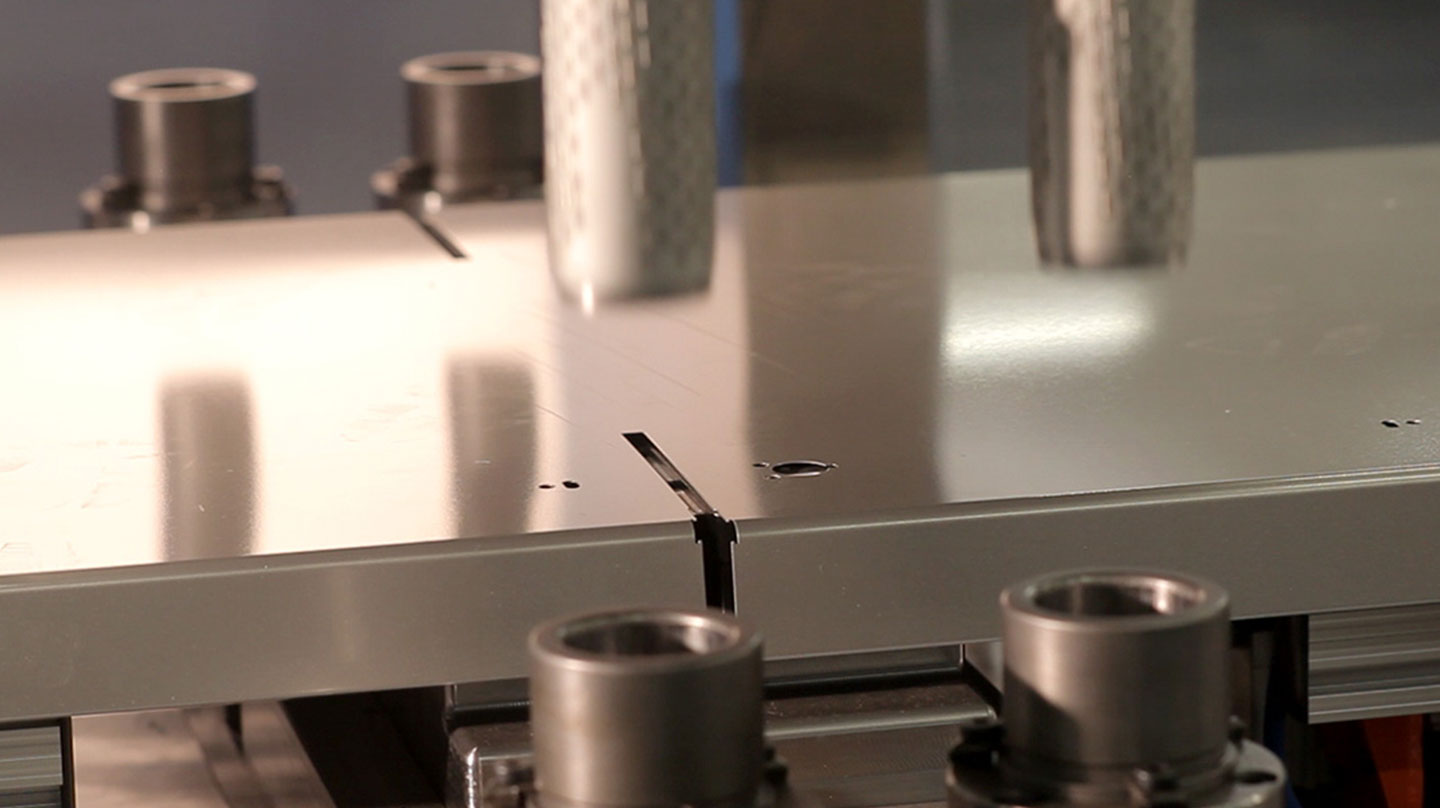

The single-stroke flanging process represents a COMI TEAS point of excellence, guaranteeing high cycle times and maximum quality avoiding the presence of multiple movements of the tool.

The diagram below summarizes the flexibility of customizing our door production lines

| FEEDING | PICK-UP & CENTRING | NOTCHING & PIERCING | PRESSES |

|

|

|

|

| BAYS MOUNT CUSTOMIZABLE | MAXIMUM ACCURANCY | FIXED OR MOVABLE PRESSES | TABLE SIZE CUSTOMIZABLE |

| FRONT/SIDE ARRANGEMENT | EXTRA LENGTH MEASURING AND TRIMMING | OPTION OF UNIVERSAL PUNCHING UNIT INTEGRATION | AUTOMATIC TOOLING LOOCKING/UNLOCKING SYSTEM |

| FIXED/MOVABLE BAYS | DOUBLE THICKNESS CONTROL | EASY EXTRACTABLE TOOLING | CAPACITY UP TO 400 TONS |

| DECOILER AND CUTTING UNIT | 2/3 AXIS PICK-UP UNITS | OPTION OF C-TYPE PRESS | ACCURATE FEEDERS |

| BENDING | DIVISION | FLANGING | UNLOADING |

|

|

|

|

| ELECTRIC INTERPOLATED AXIS | FLEXIBILITY FOR PRODUCTION | FIXED OR MOVABLE PRESSES | LENGTH CUSTOMIZABLE |

| AUTOMATIC BLADES CHANGEOVER FROM BUFFER | DIVISION OVER PRE-DIVISION CUTS ALREADY BLANKED | ONE SHOT FLANGING PROCESS FOR MAXIMUM QUALITY | SAFE AND ERGONOMIC UNLOADING POSITION |

| OPTION OF UNIVERSAL BENDING | AERIAL TRANSFER | AMOUNT OF UNIT CUSTOMIZABLE | ORIENTATION CUSTOMIZABLE |

| BLADES BUFFER | NO NEED FOR CHANGEOVER | HIGH SPEED | BUFFER INTEGRATION |

COMI TEAS supplies its lines equipped with complete sets of the highest quality moulds, entirely made in Italy.