Team composto da progettisti ed esperti di applicazione in grado di personalizzare macchine in funzione delle specifiche esigenze dei clienti

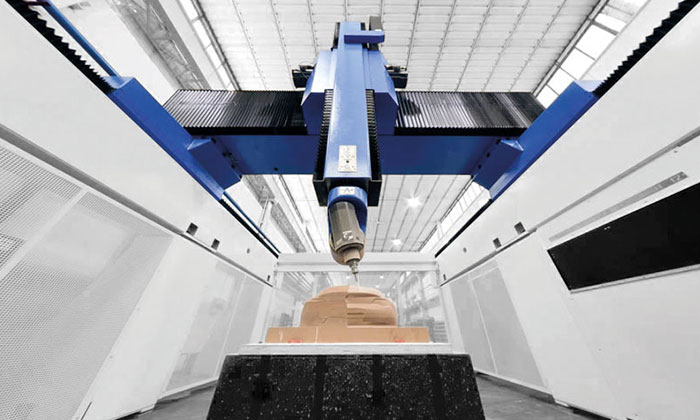

Progettazione e modellatura con software 3D, verifica strutturale con l’analisi degli elementi finiti (FEM);

realizzate con fornitori qualificati

di primissimo livello e certificata

di successo nella lavorazione di qualsiasi materiale

progettate sulle condizioni operative di specifici settori