Over 45 years’ presence in the international markets and 1.300+ plants installed all over the world, make Self Group Comi the supplier reference point for the thermoforming machines in line and single station, both in the design and in the production capacity.

for thermoforming machines employed in the refrigerators manufacturing, appliances, automotive, sanitary and industrial sectors

Top class references, all major players of the industry

Consultancy for process engineering, driven to supply the best solution to the specific customer requirements

with maximization of output and performance

which can enlarge productivity and efficiency

Mechanical systems or Laser cutting units

High quality component suppliers

Intensive Research & Development activity

Attention to power consumption

Manufacturing in Italy, quality system certified by Dekra

and efficient after-sales service

Compliancy with CE rules

The LaborForma serie’s thermoforming machines are suitable for working plastic materials HIPS / ABS / PMMA / PP in cycle, with thickness up to approx. 8 mm and PVC up to 3 mm. If equipped with dedicated accessories, they can also process materials reel-to-reel up to approx. 1 mm if rigid, higher if flexible.

These machines are suitable for the production of any thermoformed article: articles for the bathroom furniture (bathtubs, tubs, shower trays, shower walls), articles for household appliances (refrigerators, containers, vacuum cleaners), illuminated signs, helmets, etc

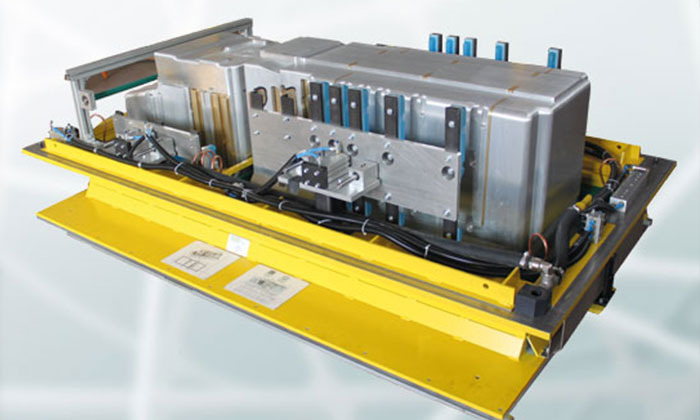

Thanks to a long-standing experience gained in 45+ years of activity, Self Group Comi designs and manufactures specific thermoforming moulds for the appliances industry, among which:

The high-quality of these thermoforming moulds, which allows an optimized material distribution and a better definition of the finished product, is then completed by the Self Group Comi technical service that support the customer from test to the final production start-up.